Sandy

New member

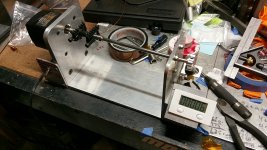

Just finishing up a simple coil winder I'm working on so I can wind up some ETD-29 and ETD-39 cores. I had a bunch of metal left over from yet another project and got to it.

I used a Hurst synchronous 30 rpm gear motor I had for yet another project.

Added a few parts from a robotics supply and here it is...

Many questions coming since I'm pretty new at all this.

Sandy

I used a Hurst synchronous 30 rpm gear motor I had for yet another project.

Added a few parts from a robotics supply and here it is...

Many questions coming since I'm pretty new at all this.

Sandy