Silvio

Well-known member

Hello fellow friends, has anyone tried this chip as an amplifier smps?

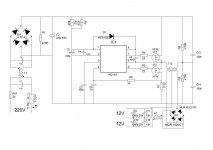

I can see that it has a soft start and also a short circuit protection. I found someone on youtube comparing the IR2153 with this chip. unfortunately it was in Russian and did not understand a word he said. The IR2161 is basically a halogen driver chip but I was wondering if it could be adopted for an amplifier smps. Anyone with better knowledge than me may say something about this chip. I am also posting the PDF data sheet.

I could see from the data sheet that it is a half bridge driver and could sink and source around 500mA on its output driver. Maybe just right for driving a couple of large fets such as the IRFP450/60 etc. It is also capable of dimming the halogen lamps it is driving. It drives in ZVS hence making little EMI. A lot of options could be made with this chip and maybe it could be driven with a PFC to control the output voltage. It is just my taught about it. I guess its worth considering building something useful for us.

I await some comments from your end.

Regards Silvio.

View attachment IR2161 datasheet.pdf

I can see that it has a soft start and also a short circuit protection. I found someone on youtube comparing the IR2153 with this chip. unfortunately it was in Russian and did not understand a word he said. The IR2161 is basically a halogen driver chip but I was wondering if it could be adopted for an amplifier smps. Anyone with better knowledge than me may say something about this chip. I am also posting the PDF data sheet.

I could see from the data sheet that it is a half bridge driver and could sink and source around 500mA on its output driver. Maybe just right for driving a couple of large fets such as the IRFP450/60 etc. It is also capable of dimming the halogen lamps it is driving. It drives in ZVS hence making little EMI. A lot of options could be made with this chip and maybe it could be driven with a PFC to control the output voltage. It is just my taught about it. I guess its worth considering building something useful for us.

I await some comments from your end.

Regards Silvio.

View attachment IR2161 datasheet.pdf

Last edited: