zeus_threat

Member

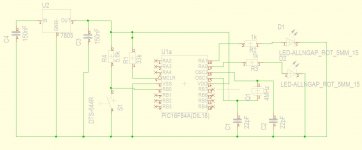

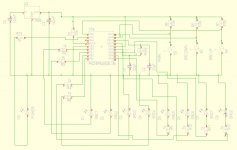

I am about to embark on a project using microchip controller and PGA2311 as a pre-amp. Am waiting for these to arrive: PGA2311 ic, HD44780 LCD, Rotary encoders, some 16F628 A to start playing with and mess around with things and some 16F877 soon to be purchased. Still deciding about Hi-tech C or assembly . I'll be using MPLAB IDE to program the microcontrollers and a pickit3 clone programmer.

Am not planning to have plenty of inputs to spare the need for additional ic's that will control relays serially.

If anybody wants to share anything you are welcome. I'll be starting as the pic arrive to build a simple power on/off and input select with leds as status display.

Then the LCD and last the PGA2311 and rotary encoders

Am not planning to have plenty of inputs to spare the need for additional ic's that will control relays serially.

If anybody wants to share anything you are welcome. I'll be starting as the pic arrive to build a simple power on/off and input select with leds as status display.

Then the LCD and last the PGA2311 and rotary encoders