obiwan

New member

Hello friends ! I have many different E , EI , ER, R cores from different manufacturers I bought sometime.

These cores are kept grouped in the same bags and boxes the day I bought them, so no mix up possible.

But they don't have any inscription, code, part no. , model, etc.

I need to determine mu permeability by using a simple method.

Earlier today I took one E 30/15/7 no gap , and calculated an inductor using the Excellent 7300 program from Starichok51

Proposed L = 703 uH

Frequency f = 60KHz

N = 21 turns

The program input/output as follows:

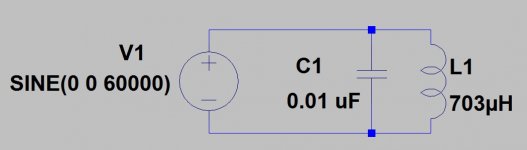

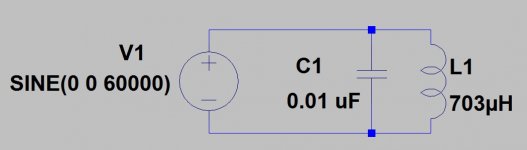

I connected a 0.01 uF known value ceramic capacitor in parallel with the coil, applied a 60 KHz low level sine wave to this circuit and monitored on my scope.

With these values of L and C , the circuit showed perfect resonance at 60 KHz with maximum amplitude of the sine wave.

Then used the formula:

u = L / Lo

... where L is the value of the inductance using the core , Lo is the value of the inductance without the core (air core)

The value of the air core resonance occurred at 954.55 KHz that means L = 2.78 uH , so

u = 703 uH / 2.78 uH = 252.8

I find that this must be wrong. When I bought these cores the material was Epcos N27 and u should be arround 1500.

So I am doing something wrong here, or the formula or method is not correct.

Could you please enlighten me !

Thank you.

These cores are kept grouped in the same bags and boxes the day I bought them, so no mix up possible.

But they don't have any inscription, code, part no. , model, etc.

I need to determine mu permeability by using a simple method.

Earlier today I took one E 30/15/7 no gap , and calculated an inductor using the Excellent 7300 program from Starichok51

Proposed L = 703 uH

Frequency f = 60KHz

N = 21 turns

The program input/output as follows:

I connected a 0.01 uF known value ceramic capacitor in parallel with the coil, applied a 60 KHz low level sine wave to this circuit and monitored on my scope.

With these values of L and C , the circuit showed perfect resonance at 60 KHz with maximum amplitude of the sine wave.

Then used the formula:

u = L / Lo

... where L is the value of the inductance using the core , Lo is the value of the inductance without the core (air core)

The value of the air core resonance occurred at 954.55 KHz that means L = 2.78 uH , so

u = 703 uH / 2.78 uH = 252.8

I find that this must be wrong. When I bought these cores the material was Epcos N27 and u should be arround 1500.

So I am doing something wrong here, or the formula or method is not correct.

Could you please enlighten me !

Thank you.