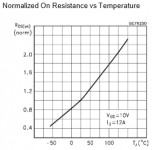

I'm in the process of doing the calculations for a 1kw half bridge SMPS, and as part of that I wanted to calculate the estimated maximum dissipation in the MOSFETs, so I can decide which MOSFETs I need and which cooling fins to put on them. Pretty much every MOSFET mentions their typical Rds on the first page, and in my case I was looking to use a pair of IRFP460's and wanted to do the calculations based on them (their typical Rds is 0R22). But when I read the rest of ST's datasheet for their IRFP460, I saw a graph that lists the Rds versus the junction temperature. However, the graph mentions that at room temperature the Rds would be 1R0, and it would take a temperature of about -100C for the Rds to be about 0R20, which is completely unpractical in real life. I'm only assuming that the low "typical" Rds resistances mentioned on the first page of the datasheet and in the description of MOSFETs at electronic component distributors is nothing but a sales trick, but under real life conditions they all have a much higher Rds than what is listed as their "typical" Rds. Is there anyone who can tell me that with certainty, or which Rds I should look for? I've added an image of the Rds vs Tj graph from ST's IRFP460 datasheet for reference.